Turtle diagrams and process maps

Does your ISO 9001:2015 documentation need them?

Turtle diagrams and process maps are intended to translate knowledge and simplify the expression of how your organisation operates and help support the communication, analysis, implementation and execution your organisation’s management system structure, its practices and business systems.

Turtle diagrams and process maps also provide the means to analyse new, or alternative process designs, and to analyse potential process changes.

Are turtle diagrams and process maps required?

While there is no requirement in ISO 9001 to use either turtle diagrams or process maps within your quality management system, external auditors often like to see use of both turtle diagrams and process maps.

These formats help them to quickly identify the resources, inputs, outputs and their interaction with other functions of the business. The decision on how you describe or communicate your business’s process interactions is completely up to you, but it is worth bearing mind that both turtle diagrams and process maps, each have their specific strengths and weaknesses as discussed below.

Why we include turtle diagrams

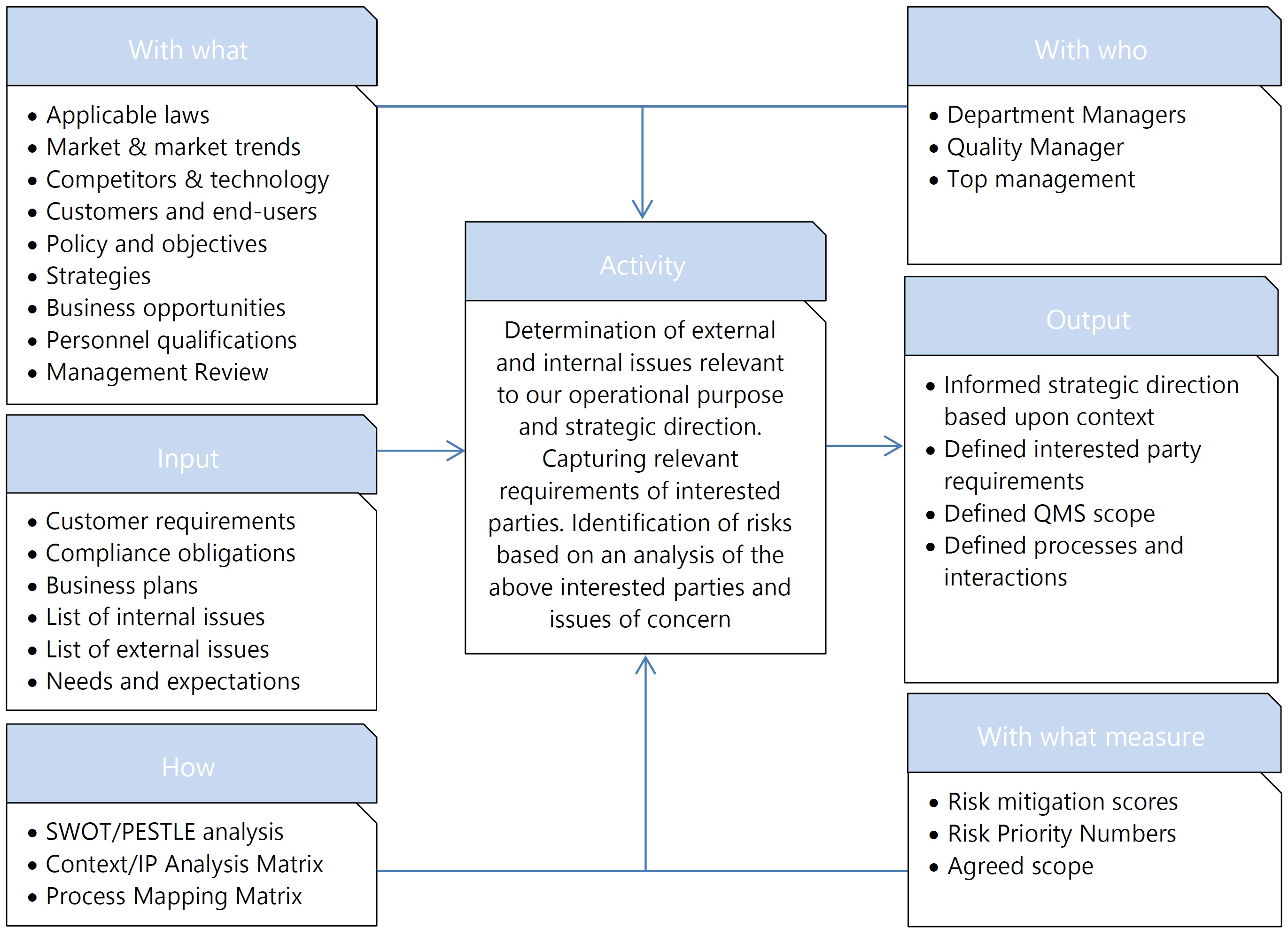

We include turtle diagrams in our quality management system procedures to assist internal and external auditors, process owners, and participants by providing an overview of the different elements that are involved and required by the process, e.g. its inputs from other processes, its outputs to other processes, who's involved, and what the deliverables are for example.

Whenever a new process being designed or a major change to a process is planned, a turtle diagram can help to identify all interested parties’ process inputs, such as; specifications, drawings, work instructions, materials, equipment, software, tooling, suppliers, skills and competencies needed by the activity to achieve its stated outputs.

Each activity is a transformation function and once the process inputs are defined, the process outputs can be identified and mapped against their respective inputs and corresponding activities.

Process outputs might include ‘products’ with destinations to internal or external customers, or assurance outputs such as maintenance and usage instructions, bills of materials, or evidence of conformance such as design review records, inspection and testing records, or customer acceptance.

Performance indicators that demonstrate process efficiency, such as; on-time delivery, budget verses actual, or process effectiveness indicators such as levels of customer satisfaction, become the inputs into the subsequent data analysis and evaluation and management review processes.

Why we include process maps

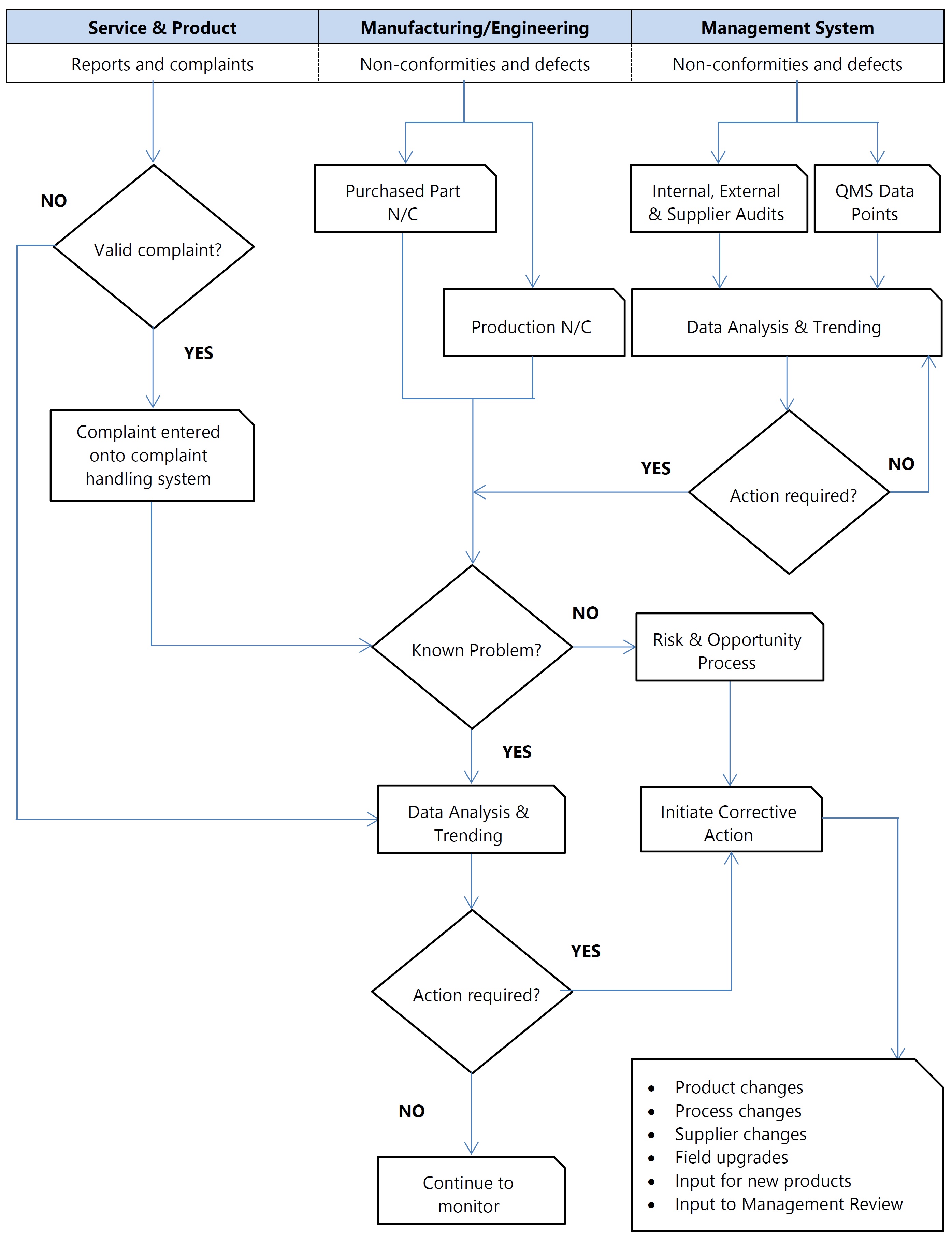

Turtle diagrams do not however show how it all fits together into a sequence of actions.

Using a top-down approach, process maps and flow charts allow us to describe how the process is structured into a hierarchy of activities and to see the sequence of steps, as well the responsibilities for each step or task.

Process maps are also able to show key decision points and multiple outputs more clearly and are often invaluable for process owners and participants.

If used well, process maps can contribute to process improvement by helping to evidence potential disconnects between tasks or departments.

Business process mapping is most effective when the consistent modelling principles apply to all parts of the model and use the same, consistent terminology and descriptions that are used and understood by your employees.

This will significantly improve the comprehensibility and minimise the omission of relevant information. Inconsistent process maps are hard for their users and stakeholders to understand.

The task of process mapping should be collaborative and incorporate the multiple viewpoints and goals of each different organizational stakeholder.

All process definition and mapping exercises must capture and analyse the complex relationships between a number of elements, such as information, people, goals and systems, as well as the underlying control and measurement methods and information flows.

As we said earlier, the decision on how you describe or communicate your business’s process interactions is completely up to you. If you choose to use them, ensure that your turtle diagrams and process maps are reviewed, approved, communicated and distributed so that they are known and understood within your organization.

Our range of ISO templates cover the requirements of ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018, and offer an easy way to implement your next management system.

More on ISO 9001:2015

How to apply the latest quality management principles

The latest and current quality management principles (QMPs), stated in ISO 9000:2015, are intended to provide the foundation by which any organization can continually improve its performance.

You can learn to apply the latest quality management principles in the context of your business's own particular operations by reviewing and documenting its activities in the context of each quality management principle.

Want to know more?

- Read our customer's feedback

- Client list - who's using our templates?

- How the templates are formatted and download examples

- Why we use turtle diagrams and process maps

- What's the difference between a process and a procedure?

- About documented information

Free management system interpretation guidance

Planning - Context, leadership and management system planning

This is the 'Plan' part of the PDCA process. Establish the objectives and processes necessary to deliver results in accordance with customer requirements and the organizational policies. This is often implemented using stated objectives, work instructions or procedures as required for consistent process output.

Doing - Support and operations

This is the 'Do' part of the PDCA process. Ensure the availability of resources and information necessary to support the operation and monitoring of your processes. This may be through management review or other methods that define resource requirements.

Checking - monitoring, measuring, analysing and evaluating

This is the 'Check' part of the PDCA process. Monitor, measure and analyse process performance. Monitor and measure processes and products against policies, objectives and requirements, and report the results. The methods employed and the timing of such analysis should be based upon priorities established by the organization.

Acting - implementing improvement actions

This is the 'Act' part of the PDCA process. Implement the actions necessary to achieve the planned results, and for the continual improvement of those processes. Auditors will expect to see evidence that corrective action is taken when measurable objectives and performance indicators fall below target or a pre-defined action level.

SSL certification

A certificate guarantees the information your internet browser is receiving now originates from the expected domain - https://www.iso9001help.co.uk. It guarantees that when you make a purchase, sensitive data is encrypted and sent to the right place, and not to a malicious third-party.

Free PDCA guidance

ISO Navigator™ is our FREE online training tool that shows you how to apply the principles of PDCA to your operations. We also offer many helpful templates that get you on the road to documenting your management system, please visit the download page.